Our Private Label

Process

CUTTING & BRINING

Beef is removed from its packaging and cut on a bandsaw by hand.

Slices are created using the FS-19 slicer to achieve the ideal thickness.

Spice blends for the brine are mixed by hand, and the beef is tumbled with the brine in a vacuum tumbler.

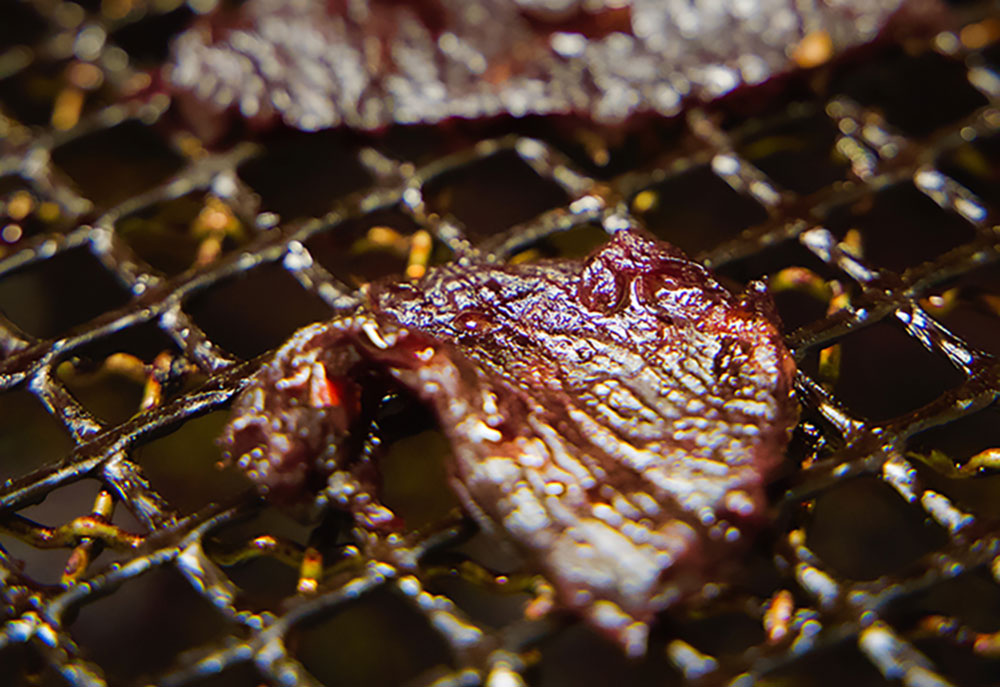

SMOKING & DRYING

Jerky pieces are spread by hand on screens to allow proper airflow during cooking and smoking.

Screens of jerky are loaded onto racks.

The jerky is cooked, dried, and smoked using cherry wood chips, in accordance with Food Standards and Labeling Policy guidelines for “Jerky” (MPR of 0.75:1 or less).

Racks of cooked jerky are removed from the smoker/oven and placed in a humidity-controlled room to cool.

Jerky is allowed to cool and dry until it reaches a temperature below the critical control point of 70°F.

Jerky is transferred by hand from screens into a sanitized buggy, then tested to ensure a water activity below 0.85.

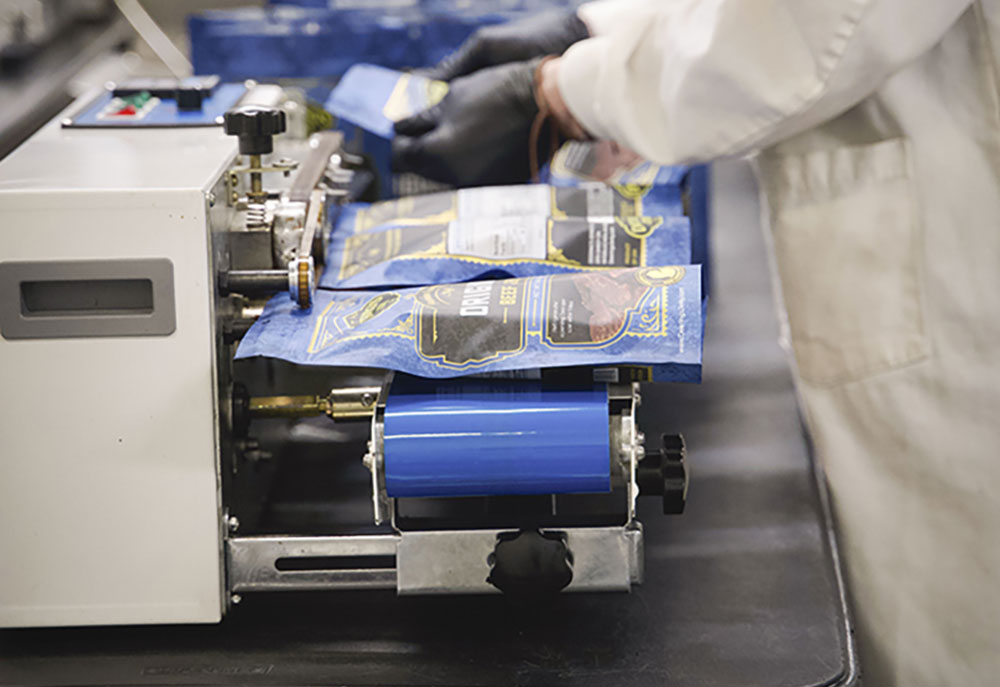

PACKING & PALLETIZING

Jerky is loaded into a multihead weigher for even distribution into 8oz portions.

Portions are packed into bags by hand.

Bags are prepared for sealing, with an oxygen absorber added for modified atmosphere packaging.

Bags are sealed using a continuous band sealer for an airtight seal.

Sealed bags are placed into a buggy and prepared for final packaging and palletizing.

Products are boxed and labeled with the appropriate EST. number, then palletized and wrapped for secure shipping.